The goal is to increase agility to handle market variations on all distribution channels and to adapt to market expectations in real time. Digitalisation of the supply chain and data management are critical challenges, and represent a real opportunity, especially in the retail sector and in stores managed directly by L’Oréal. It can provide a comprehensive view of business in a store, as well as improve understanding of the consumer purchase journey.

The supply chain network composed of 152 distribution centres is a strategic lever to ensure agile coverage of market challenges and expand our service offer. To create a more responsive supply chain, L’Oréal is investing in its distribution centres to gradually transform them into Fulfilment Centres(1):powered by automation and data, they manage a range ofservices to consumers such as personalisation, box preparation and tailor‑made delivery. They facilitate stock interoperability for omnichannel management and allow enhanced product traceability. In 2022, in Suzhou in China, L’Oréal began constructing its first “Intelligent Fulfilment Centre” to enhanceits offering of personalised beauty services and experiences.

In order to reduce its environmental footprint, L’Oréal isco‑creating with carriers low-carbon multimodal solutions adapted to the specific features of each geographic zone(green delivery, reduced air freight, hydrogen engines etc.). To improve the energy efficiency of its plants, L’Oréal is rolling out the use of 100% renewable energy worldwide. In 2022,L’Oréal and its partners opened the Group’s second largest Latin American distribution centre in Jarinu, Brazil. As aneco‑construction, this distribution centre uses 100% renewable energy.

The new Vennecy distribution centre in France has been in operation since October 2022 for the distribution of consumer products. Exemplary in terms of environmental performance (enhanced insulation, optimised mix of natural/LED lighting, passive air conditioning, roof-top photovoltaic power system and biomass-fired boilers), this centre uses data and automation to optimise flows and accentuate its ability to adapt to the markets.

Global economic performance at the service of the brands and the commercial entities

In a climate of short and long-terms global tension, the Operations Division plays a key economic role for all brands and markets, which has an impact on the overall cost of products and their distribution.

Economic optimisation efforts led by Operations involve tracking the total landed cost, i.e., the final full cost of a product, which includes the cost of packaging and raw materials, the value added by the plants and all supply chain costs.

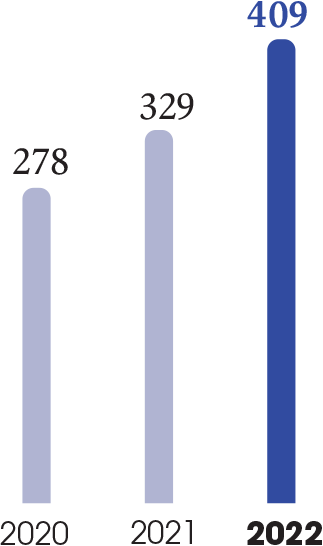

Commitment to invest in Operations

(Production and supply chain commitments in € millions)

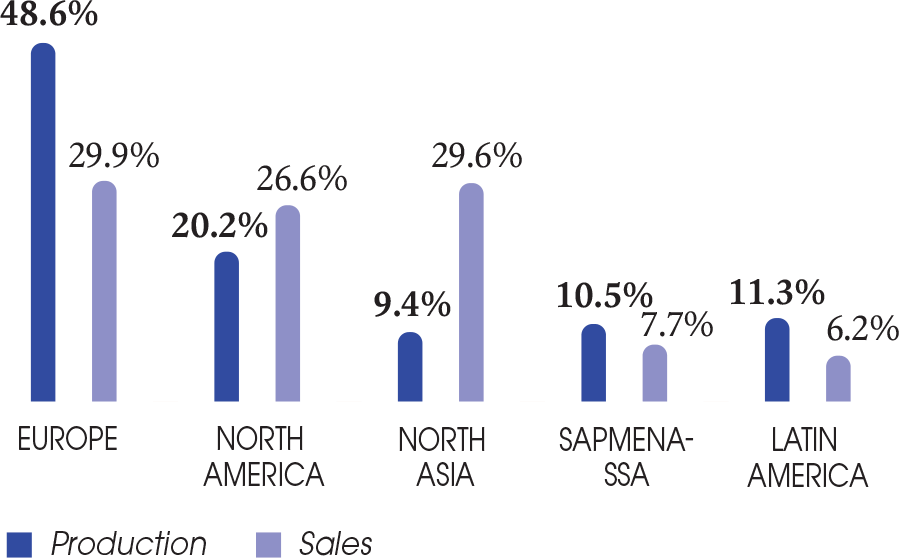

Production and sales of the operational Divisions by geographic zone in 2022: production close to its markets

(1) Distribution centres specially adapted for e-commerce distribution, where packages sent directly to consumers are prepared.