L’Oréal selects suppliers according to strict standards and criteria

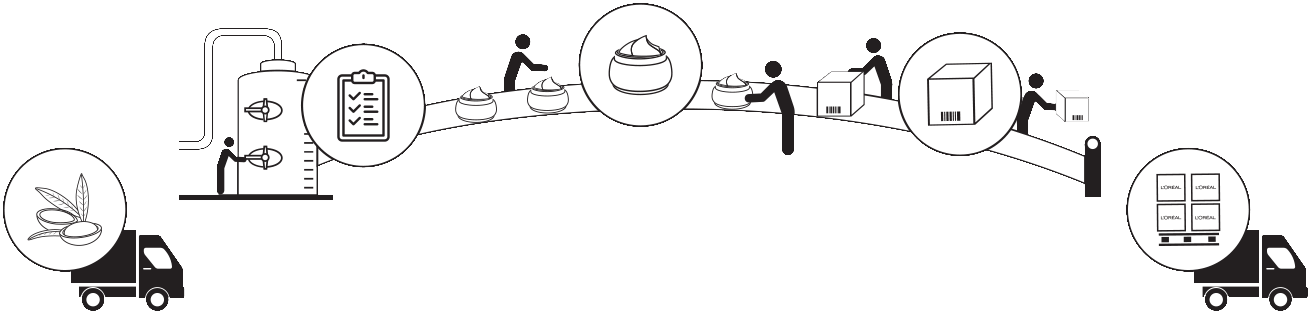

in respect of quality, safety, and social and environmental responsibility, applied worldwide and compliant with its responsible purchasing policy

~100 quality controls

For each cosmetic product

Products meet the same standards of excellence and quality all over the world

Identical processes are followed in the 38 plants, from the reception of raw materials, through the manufacturing of formulas and the packaging of finished products, until products are put on the market

100% of the Group’s

plants are ISO 22716 * compliant

97% of the Group’s

plants are ISO 9001 ** compliant

* Best practices in cosmetics manufacturing

** Quality management

In 2022, the Safety Management System, which applies to the Group’s teams and all administrative sites, laboratories, plants, distribution centres and shops, was recognised by RoSPA(1), which allotted 58 awards to L’Oréal. L’Oréal’s factory in North Little Rock, USA was a finalist for the highly prestigious Sir George Earle Trophy. This award recognises excellence in management and performance in terms of health, safety and well-being, both at and outside work.

The Group’s environmental policy aims to roll out best practices in sustainable production so as to limit the direct impact of the Group’s business activities on the environment, and to preserve biodiversity and resources: energy efficiency, use of renewable energy, optimisation of water consumption and recycling, reduction of waste generation etc. In 2022,L’Oréal continued to prioritise programmes to reduce its environmental footprint(2) with, since 2019, a 57% drop in CO2 emissions in absolute value (-91% since 2005), a -6% drop in water withdrawal per unit of finished product (-54% since2005), and a -3% drop in waste generation per unit of finished product (-40% since 2005). It should be noted that 96% of residual waste was recovered in 2022, meaning that it was reused, recycled or used for energy recovery.

(1) Royal Society for the Prevention of Accidents.

(2) Continuation of renewable energy projects around the world (e.g., start-up of two new treatment plants in France).