- optimising transport packaging of raw materials and packaging component received in the Group’s factories. The development of the wall-to-wall (1) approach is a particularly effective means of reducing waste related to the supply of components at source;

- a continuous improvement of manufacturing, filling and packaging procedures in order to reduce losses during production;

- Management of obsolete stock in order to reduce waste generation In each zone, programmes combine industrial agility and improved sales forecasts. They aim to reduce product obsolescence and improve flows via the establishment of outlets, sales to employees’ friends and family, sales to staff and donations to not-for-profit organisations.

The Group has adopted the best practices in its restaurant sunder direct management. It raises employees’ awareness of waste, ensures 100% of food waste is recovered and adapts the quantities served accordingly. It promotes responsible, fair trade and sustainable food by favouring local organically farmed produce, fair trade coffee, and seasonal fruit and vegetables. Campuses in the Paris region have committed to reducing plastic and recovering frying oils by turning them into biofuel. Two campuses have earned the “Monrestauresponsable” label for a quality food service that respects the environment.

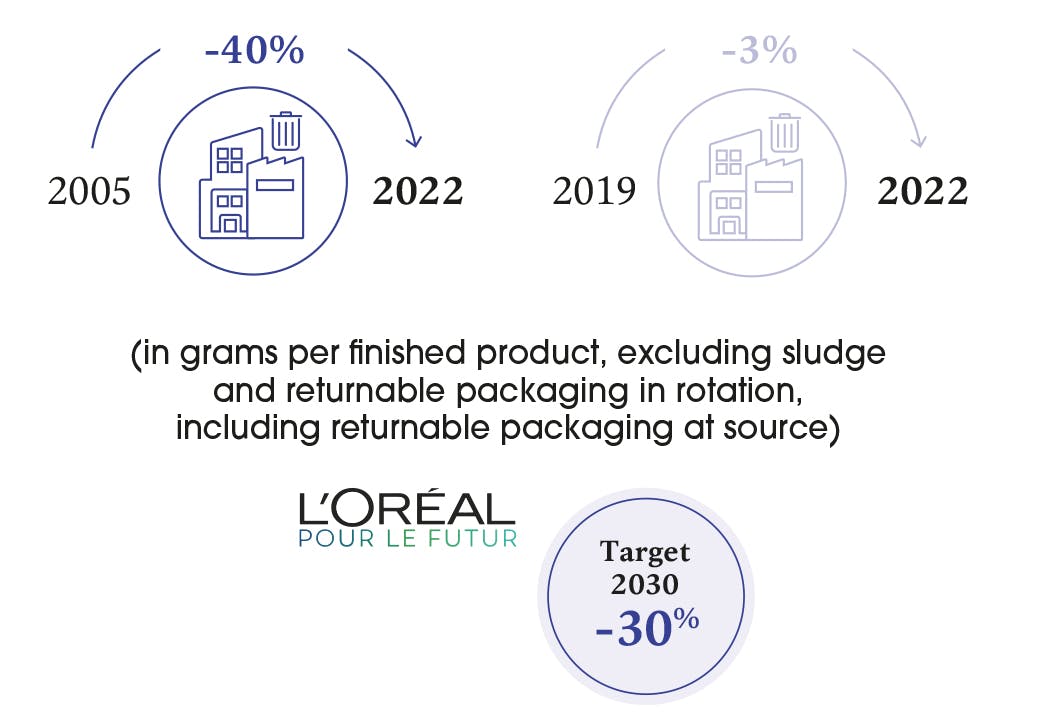

Generation of transportable waste from industrial sites

This diagram shows the generation of transportable waste from administrative sites and research centres.

From 2005 to 2022: - 40%

From 2019 to 2022: - 3%

L’Oréal pour le futur - Target 2030: - 30%

(in grams per finished product, excluding sludge and returnable packaging in rotation, including returnable packaging at source)

In 2022, 83,199 tonnes of waste were generated at industrial sites (excluding sludge)☑, an increase of 2% compared to 2019.Over the same period, the production of finished products increased by 5%. This represents 12.9 grams per finished products representing a 3 % decrease compared with 2019(-2% compared with 2021).

Generation of transportable waste from administrative sites and research centres

This diagram shows the generation of transportable waste from industrial sites.

From 2016 to 2022: - 3%

From 2019 to 2022: + 23%

L’Oréal pour le futur - Target 2030: - 30%

(kilograms per 100 hours worked, excluding sludge and returnable packaging in rotation, including returnable packaging at source)

Waste generation for the administrative sites and research centres was 5,073 tonnes in 2022 (excluding sludge), representing a 21% decrease compared with 2019. This represents 11.0 kilograms per 100 hours worked, an increase of 23% compared with 2019 (-25% compared with 2021).

Changes in waste generation intensity (in relation to the number of hours worked on site) have been significantly affected by changes in work organisation. Indeed, since the lockdown periods (still in place in China for several months of 2022), the on-site attendance rate has fallen sharply due to the extensive use of remote working.

Moreover, industrial pilot, laboratory and pre-launch testing activities, which are more related to research and development projects and new product launches, generate waste regardless of the number of employees present.

Tracking of transportable waste

In addition to tracking of waste by type, an approach to account for waste by cause has been used since 2019 at all the Group’s factories and distribution centres. This method identifies and quantifies the sources and causes of waste generation in the flows of a site. This approach strengthens the action plans to reduce waste and is an additional vector of progress for the sites.

At each Group site, specific tracking (volume try, collection streams, treatments etc.) of hazardous waste under local regulations (flammable, toxic etc.) is implemented. This tracking takes into consideration the specific characteristics of each country in which the sites operate. As with all waste, hazardous waste benefits from a continuous improvement approach.

| Hazardous waste (tonnes) | 2020 | 2021 | 2022 | Variation vs. 2021 |

|---|---|---|---|---|

| L’Oréal Group | L’Oréal Group 202017,812 |

L’Oréal Group 202119,875 |

L’Oréal Group 202223,822 |

L’Oréal Group Variation vs. 2021+20% |

| Industrial sites | Industrial sites 202017,359 |

Industrial sites 202119,260 |

Industrial sites 202223,308 ☑ |

Industrial sites Variation vs. 2021+21% |

| Administrative sites and research centres | Administrative sites and research centres 2020453 |

Administrative sites and research centres 2021615 |

Administrative sites and research centres 2022514 |

Administrative sites and research centres Variation vs. 2021-16% |

☑ The Statutory Auditors have expressed reasonable assurance about this indicator.

(1)Production of filling and packaging components close to the Group’s production facilities.